气勢如虹的一幕!

剛看到台灣收藏家許兄的牛場,真是非同尋常,而且很多都是同款幾台的那樣收,但是為何唯獨不見京商的牛們呢﹖

剛看到台灣收藏家許兄的牛場,真是非同尋常,而且很多都是同款幾台的那樣收,但是為何唯獨不見京商的牛們呢﹖

為什么說是唯一的呢﹖因為這是台經過美國一位車模愛好者自己由頭到尾改裝過的版本。

Here’s a GMP 1970 GTX a lot of you probably never saw before. That’s because I built this for a friend of a friend. I cam as close as I could to replicate the 1:1 car. This B5 beauty would’ve made an excellent candidate for a production GMP offering. Custom interior, handmade cage, and other parts from other cars. The side stripe is a water slide decal I made in photoshop, printed out, and added myself. Took me 1.5 hours to remove that vinyl roof with Z7 debonder. Overall I think it turned out nice.

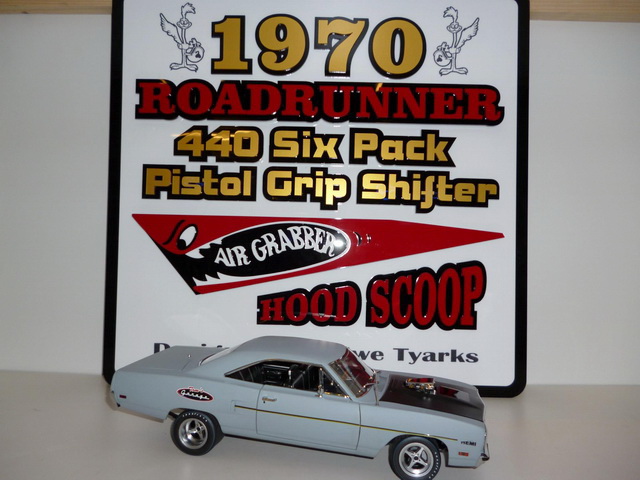

另外發現以下3台可能是唯一的GMP 1970s Road Runner,應該是美國收藏家Uwe Tyarks他自己改裝的。

這次找到一個日本的收藏家,家裡車模跟我堆的差不多高了。

今天在MC論壇看到爽域/伯陵000兄的新文章,覺得當中資料很有用,所以就轉發了過來。

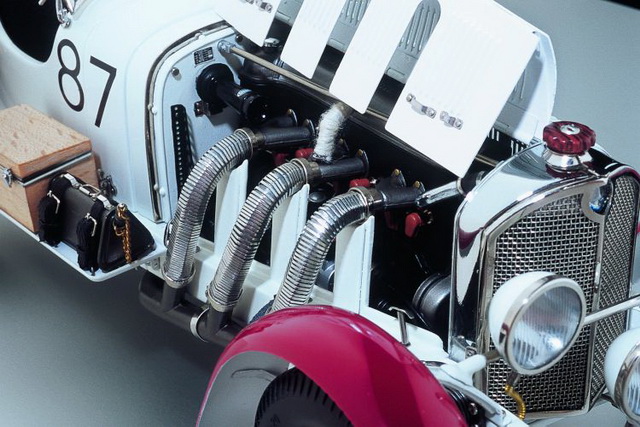

根据有關材料整理出CMC手工裝配零件數的明細。因為有大量1:24的模型沒有零件數

量記錄,1:18部分車型也沒有提供具体數字,例如:W125(M031)根据做工和出厂時

間,參照W25(M033)的情況,零件數估計應在550-650之間;Mercedes Targa Florio,

(M048)參照TIPO(M047)与W196R(M049),零件數量,估計應在800-1000之間;而

大量的編號車由于車型重复沒有單列的必要。此外1:12比例沒有數据記錄,有待統

計補充。這份不完全清單需要喜歡收藏CMC的朋友來進一步完善修訂,隨著CMC新作的推出,期

待零件數字不斷被改寫刷新,做工更加細致精准,不斷突破工藝极限。1、Mercedes-Benz SSKL, Mille Miglia, 1931 1885

2、Mercedes-Benz 300 SLR Uhlenhaut , 1955 1817

3、Ferrari Testa Rossa, 1958 1650

4、Audi 225 Front Roadster, 1935 1600+

5、Mercedes-Benz 300SLR Mille Miglia, 1955 1500+

6、Ferrari 500 F2, 1952/53 1463 (EXOTO的 1300+)

7、 Ferrari 156F1 1450 (EXOTO的 1400+)

8、 Maserati 250F Fangio,1957 1387

9、Ferrari 250 GT SWB Competizione, 1961 1300(估)

10、Ferrari 250GT SWB, 1961 1141

11、Maserati Tipo 61 Birdcage, 1961 1140

12、Mercedes-Benz W196R, 1954/55 1100+

13、 Mercedes Targa Florio, 1924 1009

14、Auto Union Typ C,Hillclimber, 1936/37 1000+

15、 Porsche 901 coupé, 1964 971

16、Bugatti T35, 1924 926

17、 Mercedes-Benz SLR McLaren 850

18、Auto-Union Typ D, 1938 680+

19、Mercedes-Benz W25,1934 610+

20、Mercedes-Benz W154, 1938 500+

21、Mercedes-Benz Racing Car Transporter 409

22、Mercedes-Benz W165, 1939 400+

23、Auto-Union Typ C, Engine, 1936/37 400+

24、Audi 920,1938/40 399

25、Mercedes-Benz 300d, 1958/62 388

26、Wanderer W25K, 1936/38 380+

27、Horch 853, closed top, 1937 350+

28、Mercedes-Benz 450SL, 1973/80 280+

29、Mercedes-Benz 300 SL, 1952 250+

30、Mercedes-Benz 540K, 1936 220+

31、Mercedes-Benz W196, 1954/55 180+

Update: July 19, 2017

Talbot-Lago, 1937 1,488

Maserati 300S, 1956 1,838

Mercedes-Benz LKW Renntransporter LO2750, 1934-38 2,365

Ferrari Transporter Fiat 642 RN2 Bartoletti, 1957, 3,115

Ferrari 250 GTO, 1962 1,841

Ferrari 250 California SWB, 1960, 1,634

Ferrari 312P Berlinetta, 1969 1,600

Bugatti 57SC Corsica Roadster, 1938 1,780

Alfa Romeo 8C 2900B, 1938 1,577

Aston Martin DB4 GT Zagato, 1961 1,825

Alfa Romeo 6C 1750, 1930 1,800

今天在MC論壇翻舊貼發現的:

Enzo是一流的商人(對市場的把握,對机遇、形式的判斷,對金錢、權力的駕馭,

擁有出色的領導才能,雖然有時有點陰),二流的賽車手(早年當車手的几年,他

沒有什么突出的成績,但他一直熱衷于賽車運動,血管里流著競速的血液),三流

的汽車設計師(雖然他沒有直接設計過任何汽車,但他畢竟是整個團隊的領導)。1929年,Enzo成立的法拉利賽車隊,這個車隊是作為阿爾法。羅密歐專職賽車隊組

建的。一直到二戰后法拉利才生產面向市場銷售的汽車。Enzo的做事為人是有商人

的奸詐,是有對妻子的不忠不義,是有對為法拉利逝去車手的冷漠無情。但他作為

白手起家的創業者還是值得尊敬的。- magic1911G

愛車之人對Testarossa的側身設計不會陌生,因九十年代的法拉利紀念品都是以Testarossa為設計主角。

永經堂集團董事任德堅,獨愛老舊的超跑,每每把握時機用最低價,快人一步買入「冇人吼」的「年輕」舊車珍藏。然後再幫襯李國寶家族都聘用的老爺車聖手,將老爺超跑翻新,好好保養,當車齡到了20歲,就在老爺車展上公諸同好。旁人欣賞的眼神、讚嘆的表情都足已令他樂上半天。

記者:吳宛蔚 攝影:梁志永

在歐美國家,車齡25年或以上的汽車才可稱為老爺車(classic car),本地門檻則低一點,20年就可以了。二、三十歲的人正值黃金十年,但二、三十歲的車,卻是日暮黃昏。任德堅獨愛老爺車,除日常代步的七人車外, 朋友說他共有七部年過十歲正步向衰亡的舊車,他笑笑口不願證實。採訪當日他駕來兩部法拉利經典型號,分別是1987年出廠、3.2Mondial2+2的 Cabriolet及1989年出廠的Testarossa。

任德堅八年前認識剛從加拿大回流、在九龍開設汽車服務中心的老爺車聖手黎建明,自此所有老爺車都由他一手翻新。他的汽車中心寬敞、光猛又整潔,可同時存放 超過15部車,一改我對車房都是骯髒的壞印象。許多顧客都說他厲害得一聽引擎聲就知道那個部件出事。雖然各大車廠都樂意維修原廠的老爺車,但任德堅與其他 老爺車車主好友自從見識過黎建明的翻新功力後,都成為他的死忠客人。李國寶家族及一眾富豪名人就是在老爺車展見過他的作品,都不再將愛驅送回原廠維修,不 惜「紆尊降貴」,親臨他位於新蒲崗的店商量維修事宜。

讀機械工程出身的他,本身就是一名車癡兼完美主義者,使用的工具全是最頂級,一般品牌出品四 呎高的工具箱只要數千元,但他卻選用索價10萬的Snap-on,「靚車一定要用靚工具,貪平使用品質參差的工具會連螺絲都磨壞。」翻新老爺車更會不惜花 上以年計的時間,當中叫他印象最深刻的,是三年前為一位城中知名富豪修復他那部1984年買入同年出產的法拉利328。

【力高汽車服務中心】

地址:新蒲崗景福街100號地下

收費:全車翻新重組由$60萬起

好多人以為 Bentley個 Logo係左右對稱,查實兩邊翼 羽毛數目唔同;左邊9條、右邊則有10條,而中間用

羽毛數目唔同;左邊9條、右邊則有10條,而中間用 黑色做地色,係代表該車系為旗下最 Powerful

黑色做地色,係代表該車系為旗下最 Powerful 。

。

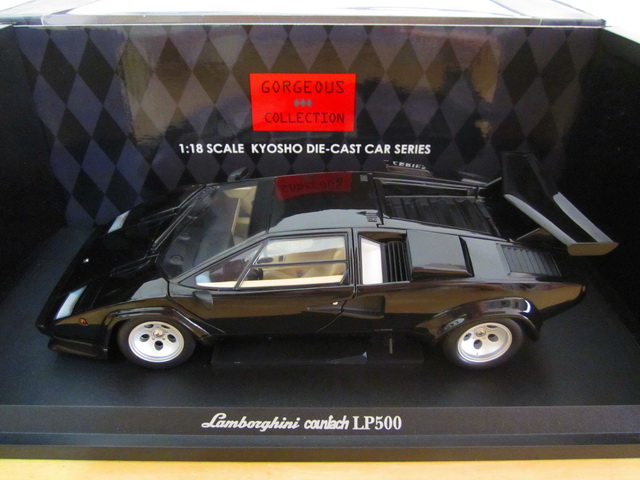

德國寄來的,前天早上剛收到,真的是一點疹子也沒有,太奇怪了! 這款黑色Countach的實在難找,而且京商搞錯了型號,應該是LP400S,不是LP500,LLPP兄弟之前指出的,我找了好久,好不容易才找到個合理价格的。

其實AA也有出同款的黑色,但是明顯京商的Countach壓得更低、更貼地面,也就是更有气勢!

真巧,同星期在本地又收到了紅色的第一版兄弟(看頭燈便知、Robin兄之前的研究碩果),也是沒什么疹子,大喜!

補充: 舊版的尾部有蝕刻片,新版的閃令令,舊版的暗啞不反光。 舊版的3色(紅白色)的頭燈橙色指示都是向內的,而只有黑色的是向外。 再版的紅色和黃色橙色指示燈都是向外的。 再者就是AA的3色Countach頭燈橙色指示都是內的。

今天在FB看到了一個美國Plymouth Road Runner的瘋狂愛好者,這位應該不止有品味,而且更有足夠的空間、財力和時間才能弄出一間如此像樣的肌肉之家。 (Uwe Tyarks)

最近在SG8論壇上看到的,這樣的規模真稱得上是嘆為觀止!

很難相像此君是如何把所有Z-TUNE的版本收齊的!

It’s Mission IMPOSSIBLE, BUT HE MADE IT!!!